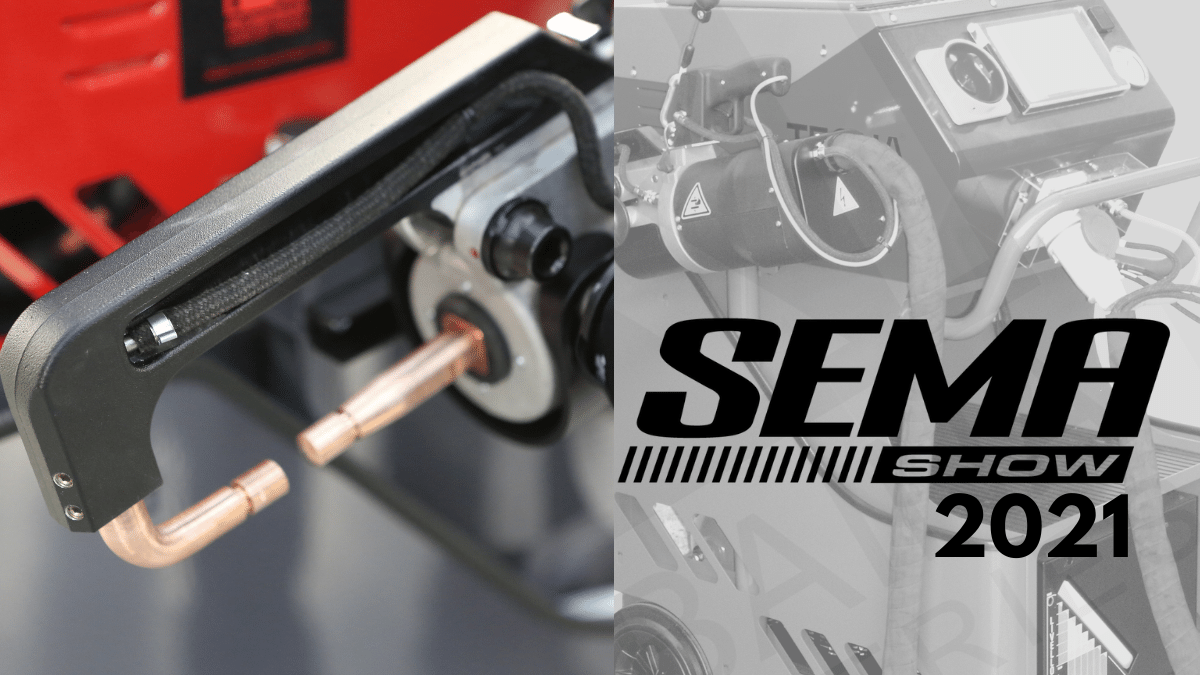

Have you checked your spot welder’s coolant level lately?

Keeping your welder’s cooling system optimized is a basic maintenance task that should never be overlooked.

Here are tips to protect your spot welder, and prevent costly project downtime and repairs.

Related Products:

TECNA 3664p Resistance Spot Welder | FAN TT 4.0 Spot Welder

Here’s What You Should Know

Depending on much a spot welder is used, the coolant level may decrease before the next service appointment.

If the welder has been serviced within the past 6 months, a coolant dilution can be added. If the welder has not been serviced within the past year, the coolant may need to be drained and refreshed.

But, Wait…Don’t Burn the Pump!

Draining and refreshing the coolant should be performed by a trained welder service technician as precautions need to be taken. Improper management of the drainage can allow air to enter the system and cause the pump to overheat or burn.

Note that your spot welder should be serviced every 6-12 months, depending on use. Refreshing the coolant is just one of the many checks performed during that process.

In the meantime, take a look at the coolant level guide on your welder.

What is the Acceptable Level of Coolant?

Most importantly, the spot welder coolant level should always be kept at the MAX line. Really?

Yes, always FULL.

This is key because the cooling system is a major factor in maintaining your welder’s performance. As welder usage varies, so does the amount of coolant.

For example, running your welder coolant level low can be compared to draining half of the coolant in your car and driving to work. Maybe your car will make it, maybe it won’t.

Additionally, the minimum coolant level is simply the lowest level the welder operates at. Any lower than that, the before the pump begins to draw in air and subsequently, burn the pump.

Therefore, a few dollars and minutes of prevention can save thousands of dollars in repairs or downtime.

What about the Coolant / Water Ratio?

It’s important to note that it is a dilution of coolant and distilled water that should be added. The ratio is 1 bottle of Redline Water Wetter mixed with 1 gallon of distilled water. The coolant is available for purchase at your local hardware store.

Not sure how much coolant is already in the tank? When in doubt, just add distilled water.

In conclusion, let’s keep it simple by maintaining your spot welder coolant level at the MAX fill line. In turn, you’ll reap the benefit of keeping your welder and your jobs running smoothly.

Need to schedule your Spot Welder Maintenance Service Appointment?

We are an Authorized Service Center for TECNA and FAN by Fronius Welders.