Mechanical Engineering Student and Shop Owner Raves Over ROBAINA’s FAN250c Welder

Written by Autobody News Staff

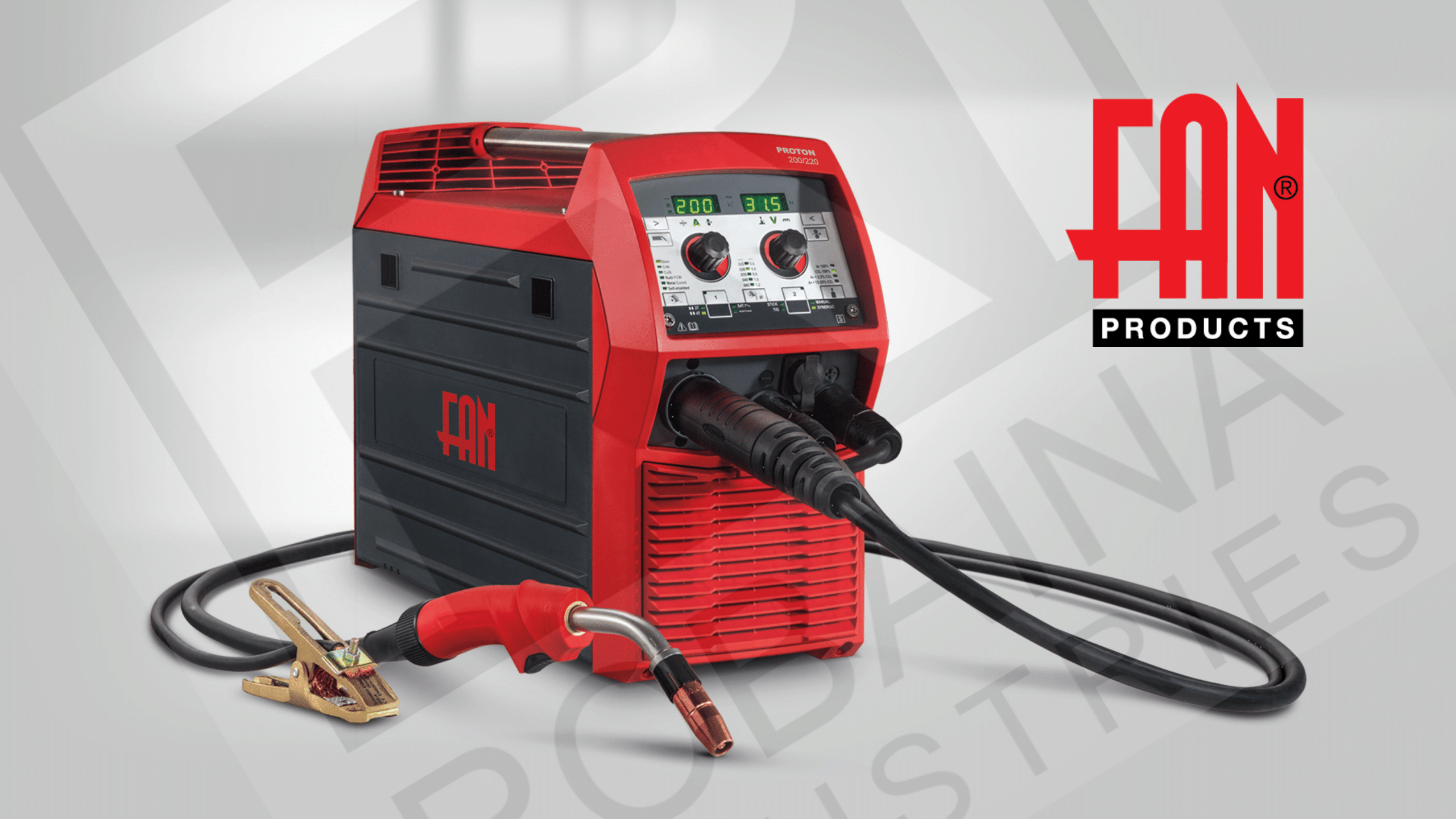

He noted, “Whether it’s the smallest detail no one sees or something obvious, the repair has to be done to the best of our ability, and to do that, we need the best equipment and proper training. It’s all about quality, so we only buy the best quality equipment that’s available, which is why we choose ROBAINA and its FAN [Fronius] 250c welder.

John Rost of German Auto Body believes in constant improvement through additional education on a consistent basis.

John Rost of German Auto Body believes in constant improvement through additional education on a consistent basis.

German Auto Body

Location: Santa Clara, CA

(408) 727-3368

www.germanautobody.com

Company At A Glance…

Type: Collision Repair

Facility Employees: 22

In Business Since: 1966

Number of Locations: One

Combined Production Space: 32,000 square feet

In early 2016, the ROBAINA team visited German Auto Body to demonstrate the FAN 250c, spending six hours with Rost’s technicians to ensure they were adequately trained on the product’s many features.

According to Rost, “The FAN 250c is extremely easy to use and outputs high quality welds quickly. Welder setup is fast and very easy because FAN made everything intuitive and ergonomic. I was really impressed with ROBAINA’s demonstration and purchased two units: one welder setup for steel and one for silicon bronze.”

Rost continued on to discuss the product’s ease of use.

“After setting up a practice weld to ensure the proper settings, it’s ready to go, and my employees love it because it makes an average welder so much better at his job,” he said.

Rost’s father, Joe Rost, founded German Auto Body in 1966, and John began working in the shop at age 16, taking over in 1988. Despite his vast industry experience, Rost’s focus on education has led him to pursue a Mechanical Engineering degree, allowing him to offer an educated perspective on the FAN 250’s technical aspects.

One of the features that makes the FAN 250c so easy to use is its option for user-defined and full digital control of its digital, pulse-like advanced features.

“The parameters are set up to take control of the welding operation in an adaptive manner in relationship to the torch distance and hand speed when corrections are needed. With other welders, this does not happen, giving FAN 250c the advantage,” Rost explained. “Once you dial in the metal thickness, wire type, material thickness and gas, the welder compensates for any fluctuations in distance or amperage. You can hear the consistency of the sound, which makes the FAN 250c different and results in much smoother welds. It’s so easy to use—the machine figures out the rest, making good welders weld even better!”

Rost praises ROBAINA’s FAN 250c welder as a high quality product that produces smooth welds.

Rost continued on to discuss some of the product’s other features.

“The torch swivels on the cable, making it easy to get around tight spaces and avoid bends in the cable that can slow the wire and result in imperfect welds,” he said.

“There’s a built-in LED on the torch too! The second LED is an internal light that assists with changing welding wire spools in dark places, and it’s very easy to change the rollers because they’re color-coded for wire diameter. Even the tensions on the rollers can be set to certain preloads. The FAN 250c has many great features that take the guesswork out of the welding process.”

Due to the microprocessor and software presets of the welder, there is minimal splatter involved with MIG welding, and the weld beads and penetration look smooth when used properly.

“The final appearance of the welds comes down to the machine and the welder,” Rost said.

“As long as the welders go through their samples and practice beads, a perfect weld is very achievable with the FAN 250c, and we can put out good quality welds all day. However, no welding product can achieve this by itself. It requires basic training to make a very good welder, but ROBAINA is great at demonstrating its products and providing the necessary training.”

The technicians at German Auto Body love the FAN 250c because it makes them better welders.

German Auto Body strives to set itself apart from the competition by constantly acquiring factory training.

The I-CAR Gold shop is also ASE-certified in addition to being OEM-certified by Porsche, BMW, Toyota, Lexus and Infiniti. “We’re our own worst critic,” Rost said.

“We’re constantly looking for flaws in our work so we can improve—[we] try to come up with better processes for longer-lasting repairs. The FAN 250c definitely helps out with the welding aspect of our repairs, and it’s an excellent welder for brazing. I’m not the least bit surprised that many OEMs have accepted it and approved it for that use. This product definitely gives the competition a run for their money!”

In response to whether he’d recommend ROBAINA’s FAN 250c welder, Rost said he definitely would, but joked that he wouldn’t want everyone to know his secret.

“But I guess that cat’s out of the bag now!” he said. “Seriously, it’s an amazing high-quality product with many advanced features, and it’s very easy to use with basic training. Still, if you’re looking for a great welder, the best thing to do is compare the product to other brands and try it for yourself. At the end of the day, I’m confident that you’d choose the FAN 250c.”

Article written and published by Autobody News, October 2017